TLV Luminaire

ZAG Engineering

Condensate drain test with test report

Our team has experience and a TrapMan testing device that is calibrated annually. Our steam specialists will prepare a detailed test report.

Condensate drain test in a laundry

Regular condensate drain tests allow defective drains to be detected early and unnecessary steam loss to be avoided.

This saves tons of CO₂ annually and significantly reduces energy costs.

The investment often pays for itself within a few months.

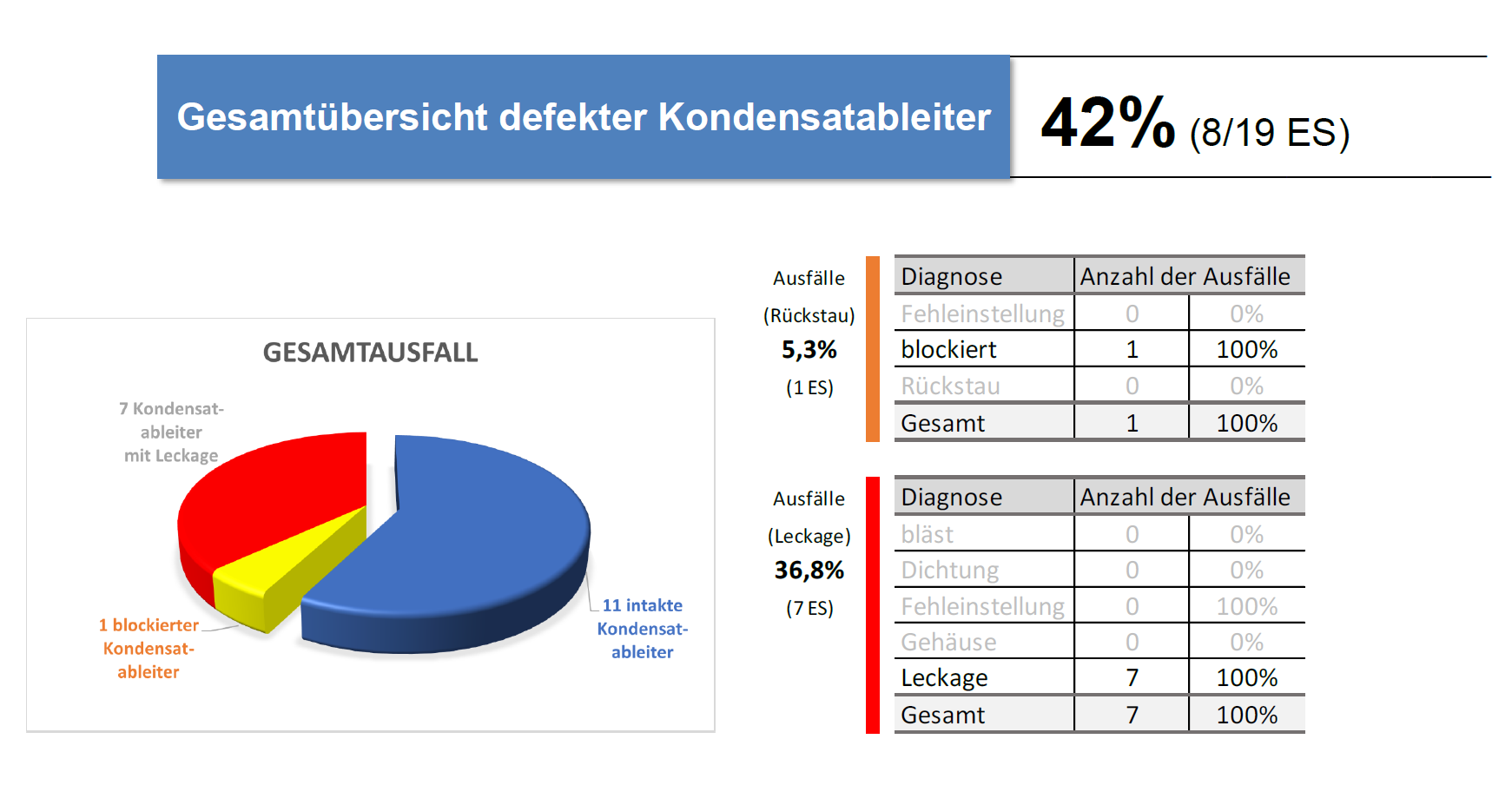

Key figures from a real audit:

42%

Defective condensate drains

(8/19 ES)

32.8 t/year

CO2 emissions

0,190 t-CO₂/t-Dampf

4,0 Mt.

Payback period

45 kg/h

Steam loss

* The values vary depending on the age of the condensate drain and how often it has already been tested.

Procedure for a condensate drain test

1. Contact

Contact us by phone, email or via the contact form.

2. Offer

Tell us the number of condensate drains you have or send us an old report, and we will prepare a quote with a budget.

3. Approve the cost estimate

If you like our offer, we will contact you with a suggested date which you can review and approve.

4. Condensate drain test

Recording of all consumers (documentation of nominal diameter, make, type, installation position, photo) numbering with a metal plate.

Measurement via calibrated testing device TLV TrapMan

All consumers must walk during the test.

5. Preparation of the test report

Analysis of the measured steam traps in a detailed measurement report. Recommendation and replacement of defective steam traps.

The project will end on time, and if you are completely satisfied.

6. Follow-up examination

During the follow-up inspection, the existing inventory list from the initial inspection is updated – taking into account any condensate drains that have already been replaced. The data entry effort is largely eliminated, making follow-up inspections significantly more cost-effective.

Your contact person

Marco Zumsteg

Sales / Technical Manager

Mail: marco.zumsteg@z-ag.ch

Direct: 41 78 694 83 83